In the past days, manufacturers and consumers didn’t worry much about part identification. But in today’s global economy, parts can come from anywhere in the world, even traveling back and forth between countries. This makes it hard for consumers and suppliers to keep track of the part ‘s original source.

The important thing it is, Traceability isn’t just for safety Government Inspectors & Officials can trace a part’s origin to ensure proper taxes & tariffs have been paid & to check for compliance with trade agreements.

You might be thinking, “We already do some kind of marking or labeling like painting or printing through inkjet, labeling, punching, etc. Do we really need advanced technology right now?. So, The truth is, with the challenges manufacturers face in industry permanent and intelligent part traceability with direct part marking is no longer simply a nice to have a process.

But Firstly, YOU HAVE TO KNOW WHAT IS TRACEABILITY?

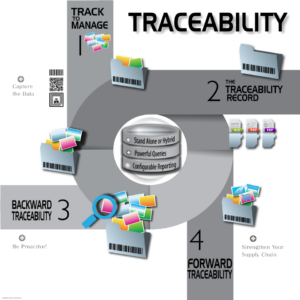

Traceability is the ability and opportunity to review the product flow throughout the manufacturing and supply chain.

The term Traceability is shaped by Trace and Ability. Traceability is the ability to trace all procedures from procurement of raw materials to production, consumption, and disposal to clarify “when and where the product was produced by whom.”

Traceability begins with directly marking parts with a permanent serial number or other unique identifiers (UID). This enables you to read that UID and track that part.

A connected Track system allows you to view the information in real-time and analyze the industrial data to make meaningful improvements.

Direct Part Marking is important here. its the only way you’re going to get permanent marks hence “lifelong traceability” There is some methods repeated use, and even painting or galvanizing can wear down marks made by inkjet, labels or other non-permanent methods, rending them unreadable.

The 2 & 3 Dimensional codes (2d & 3d codes) like the Data matrix, Qr codes can hold more information than a traditional bar code. 2D codes are also more secure when ensuring full traceability is critical and the code must be readable by scanners and readers.

Emtex offers you some methods to create permanent marks, Laser & Dot Pin Marking Machine. With the help of these machines, you can easily mark or engrave serial no., part codes, lot size, date and time, 2d & 3 d codes, etc.

Dot Pin Marking Machine

Dot pin marking machine is that kind of machine which helps to mark on curved, circular and flat surface area components through a stylus or pneumatic pin.

It provides marks by using pneumatic or air-driven based pins. The marks or impressions are provided with accuracy without exerting much pressure on the surface. The depth of the mark or imprint can be adjusted as per requirement.

Laser Marking Machine

Laser marking is the process of engraving marks on the marking surface using a laser beam. Through this technique, there is no need for any kind of inks, nor does it involve tools that contact the engraving surface which results in wear one.

Why is traceability so important?

- Opportunities to get ahead

- Increase Global Supply Chain Visibility

- Counterfeiting costs

- Increasing Industry Regulations

- Ongoing Production Dysfunctions- Inventory shortage, quality control issues, etc

- Risk Reduction

- Proof of Quality & Origin

- Transparency of all operation.

- Improve Quality & process control

- Analyzing product performance.

- Brand & Image protection

- Design Improvement techniques.

- Monitoring Process Control

- Responsibility & Safety

- Competitive Advantages

Traceability is an integral part of the automotive industry, as investigators must know where a part came from in the case of failure or part recall.

Due to improving product quality and the rise in safety awareness in recent years, traceability has been increasing in importance and spreading into a wide range of fields, such as automotive, food, electronics and pharmaceutical.

Losing the visibility to the product ‘s or material’s origin can cause production disturbances in manufacturing, costs for the producers and even serious hazards for the end-users.

Automotive parts traceability?

If your automobile industry struggling to find a marking for traceability, or simply for process improvement, so you are not the one. In the Automotive Industry, they use traditional methods for the mark on the wheel, power train, axles, engine, etc

All 3 basic criteria for modern traceability

- Permanent marked

- Easy to read

- Resistant to production line processes.

Traceability is highly important within the supply chain of any manufacturer, as it provides the ability to quickly recall items, track production and match replacement parts.

Importance of traceability in manufacturing

More and more industries within manufacturing are focusing on compliance and quality, which leads to traceability. As companies expand their businesses internationally in this worldwide economy, more regulatory mandates put commercial pressures and expectations on businesses. To manage quality recalls, risk, counterfeit parts, inefficiencies in manufacturing, and cost savings, these regulatory mandates depends on traceability. In other words, traceability acts as a risk-management tool.

Due to traceability reasons, many parts and products have to be marked with codes. Finding room on a product to place traceability content is often a challenge. Manufacturers and designers tend to use every available space on the part to squeeze all tracking information required. The marked content such as serial no., part codes, lot no., 2d & 3d codes, etc has to be readable by humans and machines. Sizing down the content is not always desirable particularly with data matrix codes and QR codes that require a minimum size as they need to be read by most commercial readers or scanners.

Having a good traceability system help the manufacturer to improve quality and efficiency, reduce costs, optimize the process and to improve the time to the customer throughout the supply chain

It also helps the companies in the industrial sector get a better handle on their product traceability. By bar codes, QR codes, DMC codes

Manufacturers use this digital technology of traceability not just for brand recognition, but for the part identification and traceability. investigators need to know where the part came from and what suppliers were responsible for its construction.

Hope this article gave you some enlighten introduction of traceability. Stay connected to

other articles.

To know more about our company and machines:-

SUSCRIBE*LIKE*SHARE*RATE

Google Review –Instagram –Facebook – Twitter –Blogger Page –YouTube – Linkedin

@barkha